Over the past decade, commercial greenhouses have expanded rapidly to meet the world’s growing food demand. However, this growth also brings significant energy challenges. Studies show that greenhouse-based agriculture accounts for 10%–29% of global greenhouse gas emissions, mainly due to heating, cooling, and lighting operations. Because traditional greenhouses often lose heat easily, energy has become one of the largest operational costs. In some regions, it can represent more than 50% of total production expenses. As energy prices continue to rise and carbon reduction policies tighten, greenhouse operators worldwide face a common question: How can we reduce energy consumption without compromising crop yield or quality?

This is where thermal screens, also known as energy-saving or insulation curtains, play a critical role. A thermal screen is far more than a simple layer of fabric. It functions as an intelligent system that integrates energy conservation, insulation, shading, and climate regulation into one. At night, it reduces heat loss; during the day, it balances sunlight and temperature. Throughout the year, it helps greenhouses maintain a stable microclimate while significantly lowering energy expenses.

Drawing on academic research and INSONGREEN’s extensive experience in greenhouse engineering, this article explores why thermal screens have evolved from optional accessories to essential systems in modern commercial greenhouses, from their energy performance to their impact on microclimate, crop growth, and return on investment.

What Is a Thermal Screen?

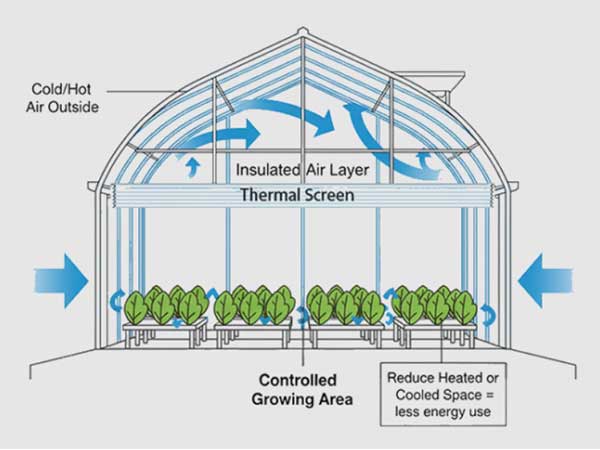

In a greenhouse setting, a Thermal Screen—also known as an energy screen, insulation curtain, or energy-saving screen—is a movable fabric layer installed inside the greenhouse, typically beneath the roof or along the sidewalls. Its primary function is to create a dynamic insulation layer that reshapes the greenhouse’s internal energy balance.

- At night, when closed, the screen forms a layer of still air between the roof and the crop canopy, reducing both conductive and radiative heat loss.

- During the day, it can be partially closed to reflect excess solar radiation, helping to lower indoor temperature while optimizing light use for photosynthesis.

- Some screens made with aluminized fibers can reflect longwave infrared radiation, returning heat emitted from plants and the ground back toward the canopy—thus raising leaf and air temperature at night.

Common types of thermal screens include: Transparent energy screens, which allow high light transmission and are ideal for low-light or winter conditions; Aluminum-coated screens, which combine nighttime insulation with daytime reflection; Blackout screens, designed for crops sensitive to photoperiod or for cooling in high-radiation regions; Double-layer screens, which deliver outstanding energy savings in cold or high-latitude climates; And diffuse light screens, which convert direct sunlight into evenly distributed light to improve canopy illumination.

In short, a thermal screen is not a passive insulation layer. Through a combination of opening, closing, reflecting, and diffusing mechanisms, the greenhouse can dynamically adapt to crop needs and outdoor climate conditions throughout the year.

The Functional Value of Thermal Screens in Modern Greenhouse Production

Building on the operating principles described above, what specific functions do thermal screens deliver in practice? The following sections examine their value across three dimensions.

1. Significantly Reduce Energy Consumption

Energy costs are often the heaviest operational burden for commercial greenhouses, especially in cold regions or areas with large day–night temperature differences. During winter, heating and nighttime insulation alone can account for 65%–85% of total energy use.

Thermal screens help solve this challenge by creating a layer of still air inside the structure, which reduces the overall heat transfer coefficient (U-value) and minimizes heat loss. At the same time, aluminized fibers within the fabric reflect longwave radiation, sending heat released from plants and soil back toward the canopy. This process directly reduces the heating demand from boilers or heat pumps.

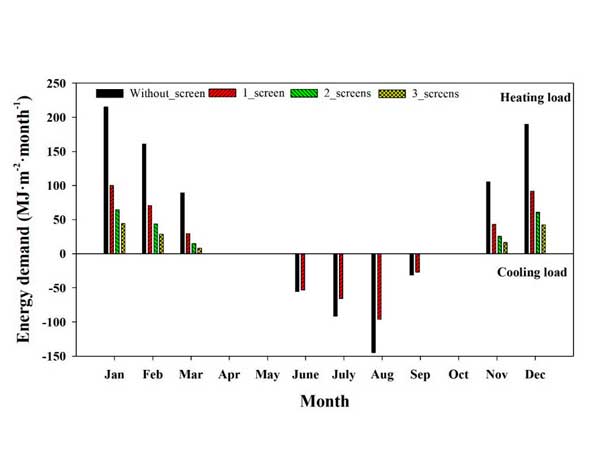

Multiple studies and simulations worldwide have confirmed these effects. A single-layer thermal screen can typically cut heating demand by 30%–50%, while double-layer systems in colder climates can reach 60% or more. Even in greenhouses covered with high-transmission film or glass, energy screens consistently deliver substantial reductions in overall energy use.

The chart above shows how installing multiple layers of screens significantly lowers heating loads during winter (November–March). A triple-screen setup achieved up to 70% lower heating demand compared with single-layer systems, and 40% lower than double-layer ones. During summer (June–September), the use of shading screens reduced cooling energy by about 25%, proving that thermal and shading screens together optimize greenhouse energy performance throughout the year. Thermal screens save heat in winter, while shading screens block excess solar radiation in summer.

2. Precisely Regulate Greenhouse Microclimate

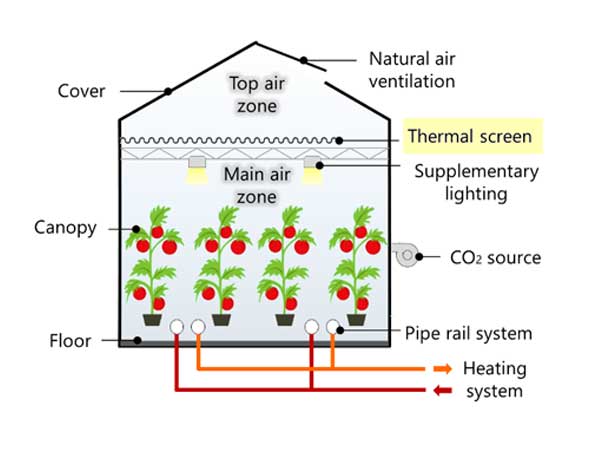

The value of thermal screens extends far beyond energy efficiency. Acting as the “climate valve” of a greenhouse, they stabilize nighttime temperatures, prevent overheating during the day, and maintain a precise balance of humidity and light through smart control strategies.

- From a temperature perspective, closing the thermal screen at night significantly reduces heat loss through the roof and helps maintain a stable air temperature inside the greenhouse. This prevents early-morning cold stress, improves the nighttime growth rate of plants, and reduces the frequent on–off cycling of the heating system.

- When it comes to humidity, closing the screen reduces air circulation, which in turn increases humidity quickly. In moderation, this helps plants by lowering transpiration and water stress. However, excessive moisture can lead to condensation and encourage fungal diseases such as botrytis or mold. For this reason, modern greenhouses often integrate the screen with their ventilation systems, using small gaps or timed ventilation cycles to strike a balance between insulation and dehumidification.

- During summer, many thermal screens serve a dual purpose of shading and cooling. Screens made with aluminized materials reflect a large portion of solar radiation when closed in daytime, functioning similarly to a shade net. This reduces the internal temperature of the greenhouse and lowers the energy required for cooling systems such as fans or wet pads, while protecting crops from excessive heat and light exposure.

- Thermal screens also improve CO₂ utilization. When CO₂ enrichment is applied, a closed screen reduces air exchange and keeps the added CO₂ concentrated around the crop canopy for longer, enhancing photosynthesis efficiency and promoting more uniform growth.

Ultimately, when thermal screens operate in coordination with ventilation, heating, lighting, and CO₂ systems, the greenhouse can follow an optimized daily rhythm: reflecting sunlight for cooling during the day, partially closing in the evening to stabilize temperature, fully closing at night to retain heat, and reopening in the morning for humidity release. This cycle enables a stable, efficient, and energy-smart microclimate throughout the year.

3. Improve Crop Growth Stability and Quality

The ultimate goal of any commercial greenhouse is to achieve higher and more consistent yields with lower resource consumption. Without thermal screens, temperature fluctuations between day and night can be large, and morning reheating tends to be slow. Such instability forces plants to spend extra metabolic energy coping with stress, which disrupts photosynthesis and growth rhythms. By stabilizing night and leaf temperatures, thermal screens reduce energy loss caused by stress, allowing crops to channel more energy into growth and fruit development. In tomato cultivation, for example, growers often observe a 2–3°C increase in nighttime leaf temperature, a 10–15% boost in photosynthetic rate, and more concentrated fruit setting with better overall uniformity.

Light management is another major advantage. Screens with light-diffusing materials improve light distribution throughout the canopy, increasing the photosynthetic rate of lower leaves by 20–30%. Crops like tomatoes and cucumbers typically show a 3–8% rise in total yield, along with more consistent fruit size and color. A stable microclimate also helps reduce diseases such as gray mold and powdery mildew, since fewer condensation droplets form on plant surfaces. This not only lowers the need for chemical treatments but also supports a healthier growing environment.

When all these benefits are combined, the results translate directly into stronger economic outcomes. With better-quality fruits, higher proportions of premium-grade produce, and improved marketable yield, growers gain a noticeable increase in revenue and profit stability. Thermal screens, therefore, provide not just an energy-saving advantage but also a practical tool for achieving higher production efficiency and consistent quality across harvests.

Greenhouse Thermal Screens Economic Benefits & Investment Logic

Thermal screens should be viewed not just as climate equipment, but as strategic energy investments. They not only lower fuel and electricity costs, but they also create long-term value by improving microclimate stability, enhancing crop quality, and supporting sustainable operations. Their economic benefits appear both in short-term cost reductions and in long-term gains related to efficiency, brand reputation, and environmental compliance. For any commercial greenhouse seeking to balance energy efficiency and high-quality production, a thermal screen is a highly worthwhile investment.

1. Cost Structure

The total investment for a greenhouse thermal curtain system generally consists of three major components:

- Curtain Material: This is the core of the entire system. Prices vary depending on the material (such as polyester, aluminum-coated composites, or polypropylene), function (insulation, shading, ventilation), and the number of layers (single or double). While high-quality screens require higher initial costs, they deliver superior durability, light transmission, and long-term energy performance.

- Drive and Transmission System: This includes gear motors, racks and pinions, push rods, and screen wires used to open and close the curtain precisely. The cost depends on the greenhouse span, total length, and automation level. In large or multi-zone greenhouses, precision and stability of the drive system directly influence the energy efficiency achieved.

- Automated Control System: This includes sensors (for light, temperature, and humidity), controllers, and software. Basic systems rely on manual or timed switching, while advanced models automatically adjust the screen based on multiple environmental factors. Although their initial cost is higher, they offer much greater potential for energy saving and yield improvement, especially in commercial facilities operating year-round.

2. Benefits and Returns

- Direct Savings: The most immediate benefit is the reduction in energy bills. By lowering heating and cooling loads, while minimizing the operating time of boilers, fans, or heat pumps, fuel and maintenance costs can drop substantially. For a 5,000 m² greenhouse, a 30–50% annual energy saving could translate into thousands to tens of thousands of dollars saved each year, depending on local energy prices.

- Indirect Benefits: A more stable microclimate leads to uniform growth, higher-grade fruits, and lower waste. When combined with a 3–8% yield increase and a higher ratio of premium-quality produce, profit margins rise accordingly. For branded growers, consistent product quality also provides market premium opportunities that strengthen competitiveness.

- Policy and Environmental Incentives: Within the broader sustainability framework, installing energy-saving equipment can qualify for government subsidies, low-interest green loans, or carbon credit benefits. Countries such as the Netherlands, Canada, and South Korea have implemented financial incentive programs for greenhouse energy retrofits. For businesses, these policies accelerate payback while improving the project’s compliance and green credentials.

3. Return on Investment and Payback Period

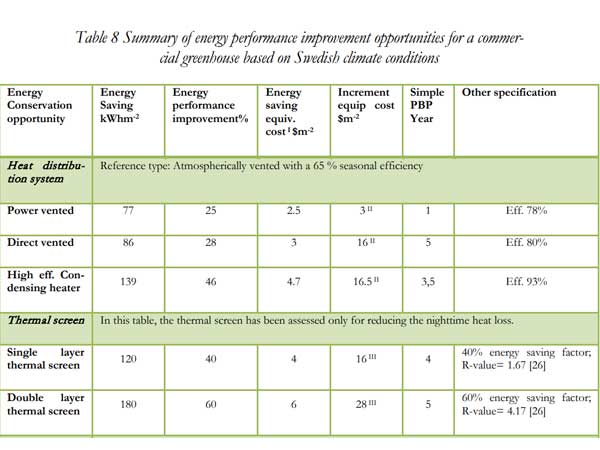

According to C. V. G. Silva, who analyzed energy performance improvement opportunities for commercial greenhouses under Swedish climate conditions in 2013, the average investment cost of a single-layer thermal screen system was around USD 16/m², with a simple payback period (PBP) of approximately 4 years. For double-layer systems, the cost increased to about USD 28/m², with a payback period of around 5 years.

More recent projects indicate even shorter payback times, thanks to rising energy prices and longer curtain lifespans. In colder climates or regions with higher fuel costs, the return on investment can often be achieved within 3–4 years. In temperate or Mediterranean regions, where heating demand is lower, growers still gain stable returns through summer shading and improved light distribution.

Conclusion

Considering all dimensions, energy efficiency, microclimate stability, crop yield and quality, and overall economic return, thermal screens have evolved from a “nice-to-have upgrade” into an essential component of modern commercial greenhouses. With a simple structure, clear working principle, and flexible control, they enable a systematic redistribution of heat, light, and humidity. As a result, greenhouses can maintain optimal performance across different seasons and climates while achieving greater sustainability and profitability.

For growers and investors planning to build or upgrade a greenhouse, thermal screens offer a practical path toward lower operating costs and reduced carbon emissions. At the same time, they strengthen product competitiveness and brand value through stable, high-quality production.

INSONGREEN specializes in providing high-performance greenhouse system solutions for global agricultural projects, including thermal screens, curtain systems, ventilation equipment, and smart control systems. We understand that every project has unique climate conditions and production goals, which is why we offer customized design and system optimization to help your greenhouse achieve the ideal balance between energy efficiency, climate stability, and yield performance. If you’d like to explore how thermal screens can improve energy management and crop production in your region, feel free to contact us today.