When summer hits, greenhouses heat up fast. Without proper protection, your crops can easily suffer sunburn—hurting both yield and quality. In commercial greenhouse operations, climate control isn’t just about cooling the air. You need a smart shading system that aligns with your crops, your climate zone, and your business goals. And at the heart of that system? The shade cloth.

This guide was created by our greenhouse design experts, with input from the product manager at INSONSHADE—one of the leading shade fabric manufacturers. Backed by hands-on experience across tropical and temperate regions, it covers everything you need to know about choosing the best shade cloth for greenhouse success. We’ll explore materials, shading rates, climate considerations, and cost-efficiency to help you find a solution that truly fits your project.

Part 1: What Is Greenhouse Shade Cloth?

In commercial-scale farming, the quality of your shading system can make or break your crop yield, product quality, and even your bottom line. And at the center of this system lies the shade cloth.

It’s not just a fabric that blocks sunlight. A true greenhouse shade cloth is a key part of managing your microclimate—regulating heat and light in a way that supports healthy plant growth and efficient operations. Unlike general-purpose shade nets used in landscaping or construction, the best shade net for greenhouse use meets much higher standards. It must deliver long-term durability, precise light control, UV resistance, and compatibility with automated shading systems.

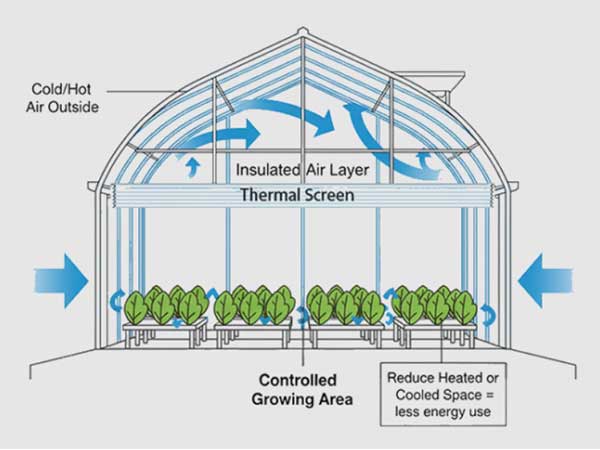

In multi-span structures, glass greenhouses, plastic tunnels, or smart-controlled facilities, shade cloth works alongside external systems like motorized curtains and internal setups such as roof vents or rolling screens. Together, they enable precise, all-day management of light and temperature—tailored to crop needs at every stage of growth.

1. Core Benefits

In large greenhouse operations, shade cloth isn’t just about blocking harsh sunlight. It plays an active role in managing light distribution, easing the load on cooling systems, and boosting crop performance.

- Reduces direct light and prevents heat stress: During hot seasons or in high-radiation zones, shade cloth filters out harsh direct light while allowing diffused light through. This helps lower leaf temperature and plant stress—reducing problems like fruit cracking or flower drop.

- Lowers heat buildup and cuts energy costs: High-shade-rate fabrics reflect sunlight, minimizing indoor heat gain. That means less strain on your ventilation or cooling systems—and lower electricity bills.

- Extends system life and reduces maintenance: UV-stabilized shade cloth lasts longer in the field, reducing how often it needs to be replaced and lowering maintenance costs over time.

- Improves light uniformity and crop quality: For high-value crops like tomatoes, peppers, orchids, or herbs, consistent lighting is key. Quality shade cloth helps deliver even light distribution, which leads to better uniformity, higher-grade produce, and greater returns per square meter.

3. Main Types

To meet the demands of different climates, crop types, and project durations, commercial growers typically choose from the following shade cloth materials:

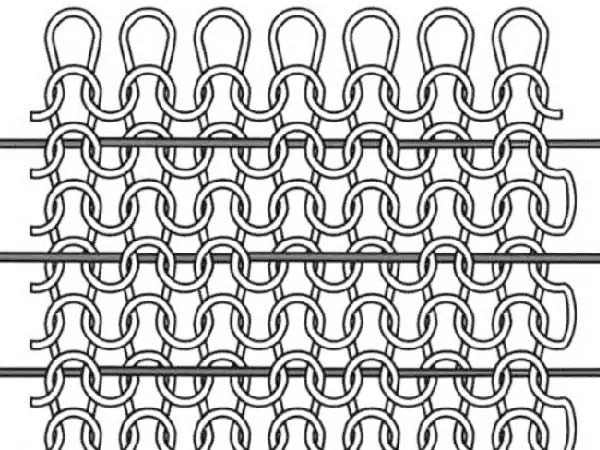

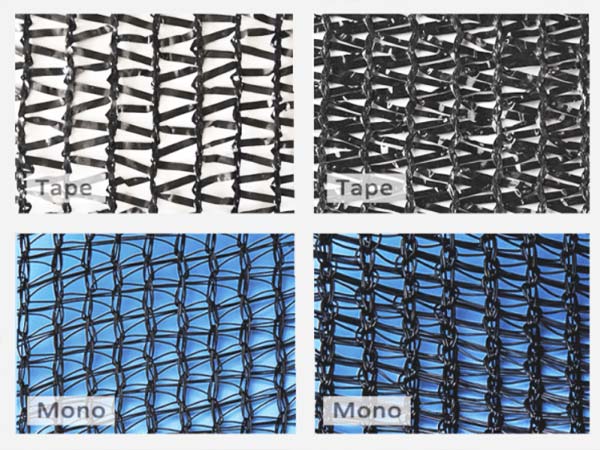

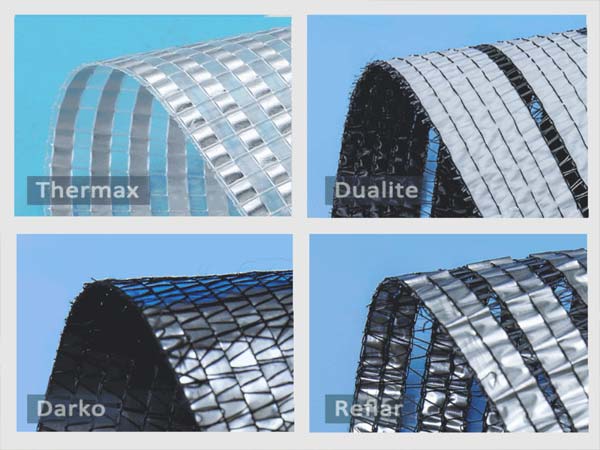

Knitted Shade Cloth

Made from flexible, high-density polyethylene (HDPE) yarn, knitted shade cloth is lightweight, breathable, and easy to install or replace. It’s ideal for medium-sized greenhouses that require strong airflow, especially in humid regions. This type is also widely used in external shading systems.

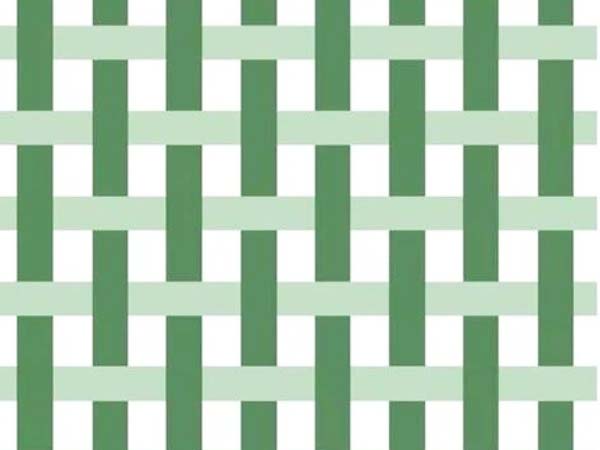

Woven Shade Cloth

This fabric features a tighter weave, offering higher strength and more precise control of light. It performs well in areas with heavy wind or rain and suits fixed-position shade systems. Woven shade cloth is especially recommended for commercial greenhouses that require strict light management.

Comparison Table: Knitted vs Woven Shade Cloth

| No. | Feature | Knitted Shade Cloth | Woven Shade Cloth |

| 1 | Light Transmission & Shading Accuracy | Good breathability and light diffusion; shading rates are diverse but less stable | More even light transmission; higher shading accuracy and better light control |

| 2 | Durability | UV-treated versions last for years; lightweight and stretchable, yet hard to tear | Stronger and more rigid; highly tear-resistant and long-lasting for fixed installations |

| 3 | Ease of Installation | Lightweight and easy to install; fits many greenhouse structures without much reinforcement | Heavier and more complex to install; needs stronger support and proper setup techniques |

| 4 | Ventilation & Heat Control | Offers better airflow, suitable for greenhouses that require ventilation and cooling | Allows airflow but less than knitted; better suited for precise light and heat control |

| 5 | Cost & Value | More affordable; good choice for budget-conscious growers | Higher upfront cost, but better long-term value for professional crop management |

| 6 | Best Use Cases | Ideal for home or small-to-mid-sized greenhouses; great for lettuce, strawberries, etc. | Ideal for high-end commercial setups like tomatoes, peppers, or light-sensitive crops |

PE (Polyethylene) Shade Cloth

Polyethylene—especially High-Density Polyethylene (HDPE)—is the most common base material for greenhouse shade cloth. It offers a practical balance between durability and cost, making it ideal for large-scale agricultural installations.

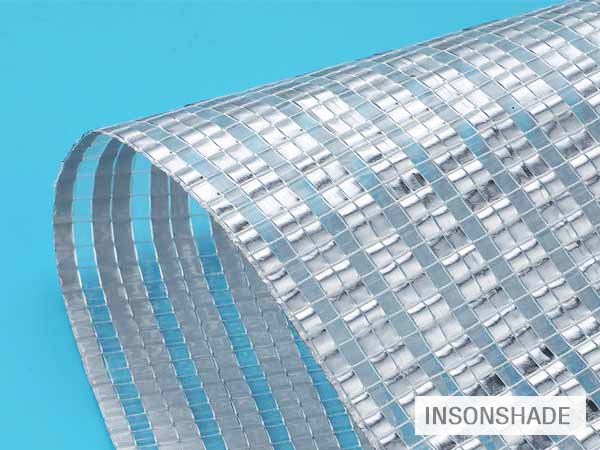

Aluminet Shade Curtain

Aluminet climate screen reflects over 90% of sunlight, making it highly effective at reducing radiant heat in greenhouses located in tropical, high-altitude, or extreme environments. It’s ideal for summer use in hot regions, but not recommended for crops that demand high light levels.

Part 2. How to Choose the Best Shade Cloth for Your Greenhouse

Now that you understand the main types of shade cloth, it’s time to focus on how to choose the right one for your specific greenhouse setup. To help you make the right call, we’ve broken the decision into three clear steps.

Step 1: Choose the Right Shade Rate Based on Crop Light Needs

In any commercial greenhouse project, the first thing to check when choosing a shade cloth is whether it can provide a stable light environment for your crops. Different crops have vastly different tolerances for light intensity and rhythms of growth. If the shading percentage isn’t well-matched, it can disrupt flowering, cause deformed fruit, or even result in severe yield losses.

Shade rate is one of the key performance indicators of a shade cloth. It tells you how much visible light is blocked. When selecting the best shade cloth for greenhouse use, it’s important to choose a shading range based on the actual light needs of your crops—not just go with a higher number or apply the same rate across all crops.

Here’s a practical reference for shade rate selection in most commercial greenhouses:

1)30%–50% Shade Rate: Best for Sun-Loving Crops

This shading range works well for most high-light crops, especially fruiting vegetables and light-dependent flowers commonly grown in greenhouses. Representative crops include:

- Fruiting vegetables: tomatoes, cucumbers, peppers, zucchini

- Vine crops: pumpkins, eggplants, watermelons

- Flowering plants: azaleas, roses, geraniums

A 30%–50% shade cloth reduces strong direct sunlight while allowing enough light for efficient photosynthesis. It’s the most widely used range for greenhouse fruit crops. During hot seasons, when combined with roof ventilation and side window systems, this setup allows for effective temperature and light control.

2)60%–70% Shade Rate: Best for Light-Sensitive Crops

If your greenhouse crops are sensitive to light and prone to sunscald or chlorosis under intense sunlight, you’ll need a higher shade rate. Fabrics with 60%–70% shade rate are recommended for:

- Leafy vegetables: lettuce, celery, romaine

- Mid-light fruits and herbs: strawberries, mint, parsley

- Shade-loving ornamentals: ferns, begonias, orchids

These crops are vulnerable to physiological stress under intense light, but they grow more evenly and with better commercial appearance when protected by moderate shading. In such greenhouses, it’s especially important to choose shade cloth with good light diffusion and uniform transmission to avoid hot spots or uneven growth.

3)80%–100% Shade Rate: For Ultra Low-Light Crops or Special-Use Greenhouses

Some crops are extremely sensitive to light and may require full protection from direct sunlight to grow properly. These are often found in settings such as:

- Nursery greenhouses (for tomatoes, peppers, melons)

- Mushroom farms (enoki, shiitake, oyster mushrooms)

- Moss and medicinal herb production

- High-value crop facilities (e.g., medical cannabis cultivation)

In these cases, 80%–100% shade cloth can be used, often combined with supplemental lighting or zone-based light control strategies. For example, in many North American cannabis facilities, dual-layer shading (external + internal) is paired with automated photoperiod systems to optimize the accumulation of active compounds.

Note: Shade Rate ≠ Performance

Even shade cloths with the same shading percentage can vary in how they affect crops. Factors like light diffusion, color reflectivity, and uniform transmission can all influence plant behavior. It’s best to choose cloth from a professional manufacturer—and consider whether the fabric includes features like diffuse light design, UV protection, or adjustable mounting options.

Step 2: Match Shade Cloth Type and System to Local Climate

Commercial greenhouses are often built in regions with dramatically different climates—from hot tropical zones to temperate four-season areas, dry inland plateaus to humid coastal zones. Even when growing the same crop, your local climate can significantly affect which shade cloth and setup you should choose.

If you only focus on shade rate or material type and ignore local weather patterns, you could end up with poor airflow, ineffective cooling, rapid material aging, high energy costs—or worse, damaged crops. That’s why matching both material type and shade system configuration to your climate is a critical step in greenhouse design.

1) Tropical Regions (Year-Round High Heat and Intense Sunlight)

Representative areas: South Asia, the Middle East, Southeast Asia, equatorial Africa

Main challenges: Intense radiation, high temperatures, and high humidity all year long

Recommended configuration:

- Shade rate: 50%–75%

- Material: HDPE knitted shade cloth (better ventilation) or Aluminet shade cloth (high reflectivity)

- System: Use motorized external shade screens with rooftop ventilation for dynamic cooling

Tip: Choose UV-stabilized cloth to extend its lifespan. This prevents frequent replacements due to damage from strong sunlight and moisture.

2) Subtropical Monsoon Zones (Hot Summers, Mild Dry Winters)

Representative areas: Southern China, southern Japan, U.S. Gulf Coast

Main challenges: Hot, humid summers and mild, dry winters

Recommended configuration:

- Shade rate: 60%–70% in summer, reduced to 30%–40% in winter

- Material: Lightweight knitted shade cloth, easy to retract and redeploy

- System: Use a dual-layer (internal + external) shading setup—double layers in summer, single layer in winter—for year-round flexibility in light control

In these climates, growers often use seasonal shading strategies, such as swapping shade fabrics with different rates or using motorized systems that can adjust the shading angle depending on the season.

3) Temperate Regions (Four Distinct Seasons, Large Temperature Swings)

Internal shading system inside a greenhouse

Representative areas: Most of Europe, temperate parts of North America, northern China

Main challenges: Low temperatures and weak light in winter; high temperatures and strong sunlight in summer; large seasonal variation

Recommended configuration:

- Shade rate: Adjustable 30%–60%; shade cloth may not be used at all in winter

- Material: Medium-density woven shade cloth, wind-resistant and weatherproof

- System: Use retractable internal shading systems combined with rooftop venting. In winter, retract the shade cloth to maximize light exposure. In summer, extend the cloth to block excess sunlight.

In temperate climates, growers typically rely on shading during the summer months. During spring, fall, or winter, the system is often kept open or removed entirely to let crops absorb as much natural light as possible.

4) Arid / Highland Regions (Strong Sunlight, High Winds, Low Humidity)

Representative areas: Northwest Africa, Central Asia, inland plateaus

Main challenges: High UV levels, frequent strong winds, dry air, wide day-night temperature swings

Recommended configuration:

- Shade rate: 40%–60%

Material: High-density woven shade cloth with strong tear resistance and wind pressure durability - System: Use fixed external shading systems to prevent flapping in the wind. Alternatively, install automatic roll-up systems that can retract quickly when strong winds are forecasted.

In these regions, physical strength and aging resistance of the shade cloth are especially important. Without the right materials and setup, shading systems can easily tear in high winds, leading to costly repairs and potential crop damage.

Final Note: Shade cloth performance isn’t one-size-fits-all. It only works effectively when it’s selected in harmony with your local climate, greenhouse structure, and crop goals. If you’re unsure which setup to choose, consult a greenhouse expert with regional experience. The right design should combine climate data and real fabric performance to create a shading system that works.

Step 3: Align Shade Cloth Choice with Budget and Use Case

In commercial greenhouse operations, choosing shade cloth isn’t just about comparing materials—it’s a long-term investment that directly impacts operational efficiency and crop outcomes. Your ideal material depends on both your budget and your production goals.

If you’re running a small-to-medium-scale greenhouse or testing a short-term crop cycle, consider using knitted polyethylene shade cloth. This combination is lightweight, cost-effective, and easy to install or swap out, making it perfect for seasonal use or budget-conscious growers.

On the other hand, if you manage high-value crop production—such as premium vegetables or flowers—a woven cloth or aluminet composite is a better fit. Though the initial cost is higher, these materials last longer, offer more stable shading, and provide better long-term returns. They help increase crop quality, reduce energy consumption, and lower replacement frequency over time.

For ultra high-value crops like orchids or medical cannabis, quality shade cloth can directly influence plant quality and market value. In such cases, ask yourself:

- Does the cloth support integration with automated systems?

- Does it provide strong diffuse light properties?

- Are detailed technical specifications available to support precise climate management?

Conclusion

Choosing shade cloth isn’t just a fabric decision—it’s a key part of your greenhouse’s climate control system, crop quality strategy, and energy management plan. The best shade cloth for your greenhouse is one that fits your local climate, crop light needs, budget, and long-term operational targets.

If you’re planning a new greenhouse or looking to upgrade your current shade system, the team at INSONGREEN is here to help. Our experts can recommend custom shade cloth solutions based on your growing region, crop types, and business objectives, ensuring every investment leads to more efficient, stable, and profitable operations.