The agricultural industry has been undergoing technological transformations consistently. Today’s smart commercial greenhouses integrate contemporary technology with traditional farming practices, ensuring that plants are provided with the optimal growth environment under varying conditions. The automation technologies in use not only significantly reduce labor costs and errors but also guarantee continuous and stable production.

You May Like: 18 Different Types of Commercial Greenhouse

With the evolving environmental changes and the impact of global warming on agriculture, such smart and automated management will offer sustainable agricultural solutions for the future. In fact, advancements in automated greenhouse technology have already transcended Earth: NASA, in collaboration with various academic institutions, is ardently working on greenhouse technologies suitable for the Moon and Mars, aiming to provide continuous life support for deep-space astronauts.

In this article, we will delve into the nine crucial components of an automated greenhouse system. These components are pivotal to realizing the automation and smart management of commercial greenhouses. They collectively create a synergistic ecosystem for greenhouses, ensuring an optimal environment for plant growth. Without further ado, let’s begin with the first component:

Part 1: Temperature and Humidity Control

A greenhouse functions similarly to the refrigerator in our homes. Just as we maintain a certain fridge temperature to ensure the freshness and taste of our food, plants also require a suitable temperature and humidity within the greenhouse for robust growth. This not only affects their growth rate and fruit quality but also determines their susceptibility to diseases. However, the temperature and humidity are not uniform throughout the greenhouse, much like how the top and bottom of a room can differ in temperature.

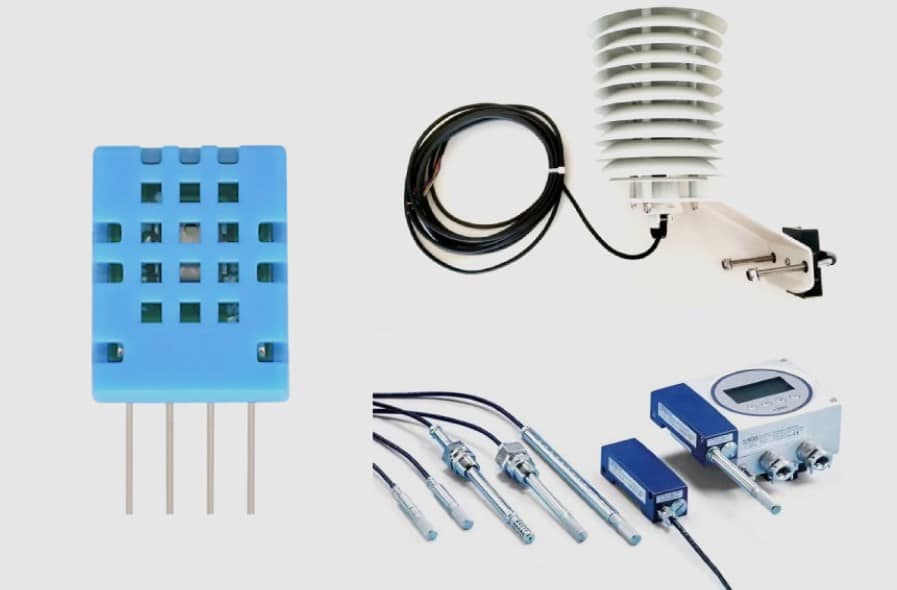

Additionally, when providing supplementary lighting for plants, these lights produce heat, which can potentially cause the greenhouse to overheat. To address this, various temperature and humidity sensors are available, including air temperature and humidity sensors, substrate temperature and humidity sensors, and liquid temperature sensors. They assist us in precisely controlling these crucial parameters.

Part 2: Light Control

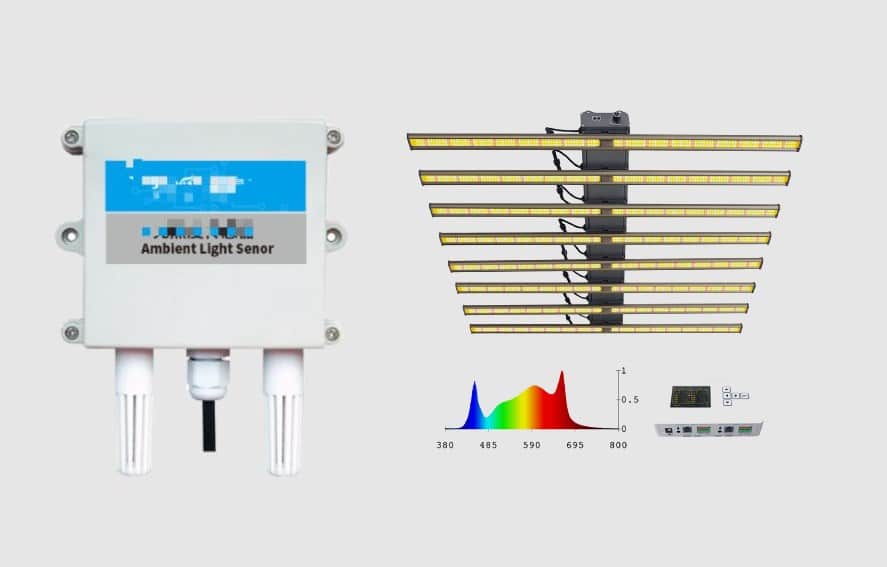

All plants rely on photosynthesis for growth. Through this process, plants absorb light energy, utilizing it to convert carbon dioxide and water into food while releasing oxygen.

For this process to be efficient, managing light becomes a pivotal step in cultivation. Whether it’s via shading devices or supplemental plant lights, it’s all about ensuring that plants receive the right amount of illumination. However, it’s worth noting that merely providing light is not sufficient. Without adequate carbon dioxide, the efficacy of photosynthesis diminishes.

Plants require different types and intensities of light at various stages of their growth. Using light modulators specifically designed for plants ensures they get the right kind of light at the right time. This equipment includes light intensity sensors, greenhouse film roll-up motors, shading film controllers, and a variety of plant grow lights.

As for the plant lights, there are many options available in the market. Each type of light has its specific size, power, and spectral characteristics. Therefore, when making a choice, it’s crucial to consider the specific needs of your cultivation or consult the manufacturer for advice.

Part 3: Water Control

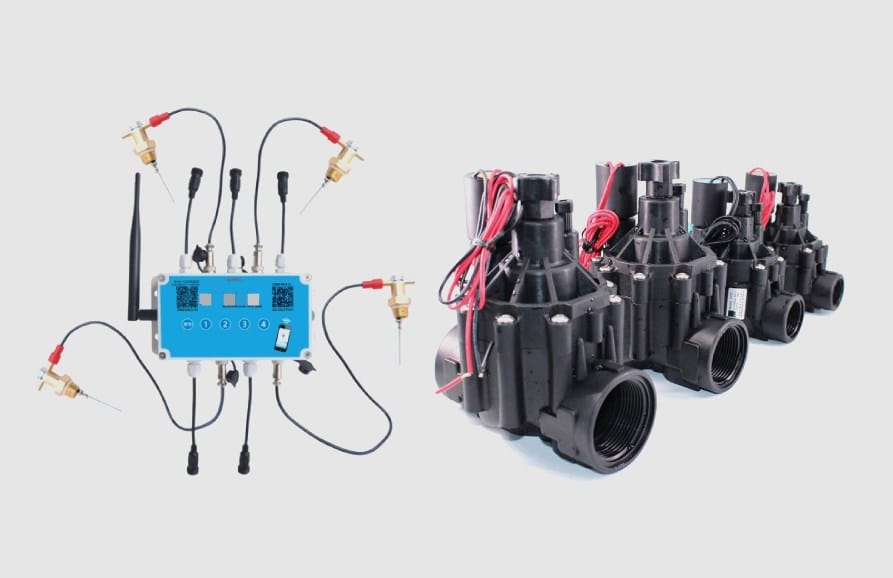

Water plays a pivotal role in the life cycle of plants. Various irrigation methods aim to provide plants with the appropriate amount of moisture. Before irrigation, filtering impurities from the water is crucial to ensure its purity, offering plants the optimal environment for growth. The pH level (acidity or alkalinity) of the water also influences plant growth, necessitating monitoring and adjustments using pH sensors. Furthermore, liquid fertilizers can be directly incorporated into the irrigation water, facilitating integrated irrigation.

Related Article: 6 Most Popular Irrigation Systems for Greenhouses

The irrigation method varies depending on the type of plant and cultivation conditions. While drip irrigation and flood irrigation are common, modern agricultural techniques are increasingly leaning towards tidal irrigation. This is because certain irrigation methods, like drip or hydroponics, might impede the respiration of plant roots. The “dry thoroughly, then soak thoroughly” irrigation technique better meets the physiological needs of plants, aiding them in accumulating dry matter more effectively.

Tools and equipment ensuring proper irrigation include water flow sensors, flow meters, electromagnetic valve controllers, water temperature sensors, and liquid level sensors. Using these devices, one can more precisely control and monitor the irrigation process, ensuring plants receive the required water.

Part 4: CO2 Control

Plants absorb carbon dioxide and release oxygen in the presence of light, but reverse the process in the dark. The concentration of carbon dioxide directly impacts plant growth, especially within greenhouses. When under artificial lighting, merely increasing the light without providing enough carbon dioxide can hinder plant efficiency.

Naturally, the atmosphere has around 400 ppm of carbon dioxide. However, in high-intensity artificial lighting setups, maintaining a level between 440ppm and 600ppm is ideal.

Carbon dioxide can be supplemented to plants either using cylinders or carbon dioxide generators. Although cylinders are more suitable for small-scale cultivation, they can be costly. For larger-scale farming, carbon dioxide generators are recommended. Ammonium bicarbonate reactive systems are safer than those burning natural gas because the latter can produce harmful carbon monoxide in enclosed spaces.

Essential equipment in this domain includes carbon dioxide sensors, TVOC sensors, ammonia sensors, oxygen sensors, and carbon dioxide generators.

Part 5: Nutrient Control

With the advancement of modern agricultural technology, the use of liquid fertilizers has surged, increasingly becoming the primary choice for fertilization. The main advantages lie in the simplified and automated fertilization process, combined with the integration of nutrient solutions with irrigation water, offering plants an immediate nutrient supply. Additionally, liquid fertilizers enable meticulous management, granting agronomists clearer insights into cultivation feedback. While current liquid fertilizers predominantly rely on inorganic salts, it’s anticipated that organic nutrient solutions will dominate in the future.

To guarantee the quality and efficacy of liquid fertilizers, it’s essential to continuously monitor their Electrical Conductivity (EC) and pH levels. These metrics can fluctuate over time and with changes in the liquid’s condition. To ensure accurate sensor readings, it’s recommended to calibrate regularly using standardized EC and pH testing solutions.

Relevant automated tools in this realm include EC sensors, pH sensors, and integrated fertigation systems.

Part 6: Video Surveillance

Cameras, serving as visual sensors, have become indispensable tools within planting greenhouses. With continuous and high-definition video feedback, growers can remotely monitor the external conditions of the greenhouse and the growth state of plants in real-time. This allows for the prediction of potential issues, and based on these observations, quick adjustments can be made to automated control strategies to ensure an optimal environment for plant growth.

In the era of high automation and Internet of Things (IoT) applications, the role of cameras and other visual devices is becoming increasingly crucial. To guarantee smooth data transmission and efficient real-time monitoring, network cameras have high bandwidth requirements. It’s recommended that video data streams and control signals utilize independent communication channels.

Essential tools in this domain include high-definition cameras, real-time monitoring hosts, optical fiber transmission modules, and high-performance switches.

Part 7: Power Management

Bio-supplementary lights in planting greenhouses are pivotal for healthy plant growth. However, they are also high-energy consuming devices, making greenhouses significant electricity consumers. Moreover, many devices used in automated greenhouses rely on electricity for regular operation.

Hence, tools and equipment in this regard encompass smart meters, intelligent electrical boxes, multi-route smart switches, air switches, contactors, and industrial power supplies.

Part 8: Pipes/Lines/Channels/Racks

A smart greenhouse represents a meticulously designed system, encompassing buildings, pipes, wiring, planting channels, and layer racks. Each component plays a pivotal role, ensuring plants receive the right conditions for growth.

Buildings: Greenhouse structure and curtain system offer protection, creating a stable indoor environment for plants, shielding them from adverse weather and pests.

Pipes and Wires: Acting as the “veins and nerves” of the system, they transport nutrients, water, electricity, and data, guaranteeing the greenhouse’s smooth operation.

Planting Channels and Containers: Directly interacting with plants, they hold plants and offer a cultivation medium. Their design significantly impacts plant health and growth.

Layer Racks: They provide support for plants, ensuring ample light and air circulation, and optimizing the utilization of space.

Part 9: Climate Control System

The various tools and devices utilized in an automated greenhouse can be likened to the different parts of a body, with the control system acting as the brain and nervous system. It unifies, regulates, and monitors all the equipment, ensuring a smooth and stable agricultural production process.

Choosing an automated device often means also choosing its integrated greenhouse climate control system. This is because each device has its specific technological framework and communication protocols, which align more harmoniously with its proprietary control system. Attempting to integrate and control devices from different manufacturers using an external cloud backend might face numerous technical and compatibility challenges, resulting in project delays or unstable operations.

Therefore, to ensure the stability and efficiency of the entire automated greenhouse system, selecting a well-adapted and established control system is crucial. Not only should it possess high compatibility, stability, and security, but it should also have a user-friendly interface and robust data analysis capabilities, assisting smart greenhouse managers in making more precise decisions.

Conclusion

With the continuous advancement of technology, automated greenhouse systems have evolved from simple planting equipment to a highly intricate ecosystem. These nine components not only ensure the healthy growth of plants but also guarantee the efficiency, reliability, and sustainability of the entire system.

As we have observed, modern agriculture is no longer just about basic farming. Instead, it merges technology and innovation, offering us unprecedented possibilities. In the future, we anticipate these automated greenhouse systems to consistently bring us higher agricultural yields, reduced resource consumption, and a greener, more sustainable future.